MeiXun (Wuxi) Communication Technology Co.,Ltd

About Us

Db design (Shanghai)/MEIXUN (Wuxi) is a quality manufacturer of RF/Microwave components. Company established in Shanghai in 2012. Due to the enlargement of production line, we moved to Wuxi city in 2019.

Company Positioning: Deeply cultivate the microwave device field and strive to be a leader.

Market Policy: Enhance the brand value of customers with high-quality products and services.

Market Strategy: Same quality + better price + better service + independent controllability.

-

30%

R & D Design Team

-

10%

Management Team

-

50%

Production Team

-

10%

Marketing Team

High-tech Enterprise, Feifeng Talent

Technical Background

Chief Engineer Wang graduated with a master's degree in high-power microwave from the Institute of Electronics, University of Chinese Academy of Sciences. In the same year, he joined CETC 40/41 for work and study. He has been committed to the design and development of microwave switches for a long time. He has applied for 27 patents as the first inventor in the microwave switch field, with 6 authorized invention patents and 14 utility model patents. The products he developed cover various application platforms such as civilian testing, vehicle-mounted, shipborne, airborne, and missile-borne.

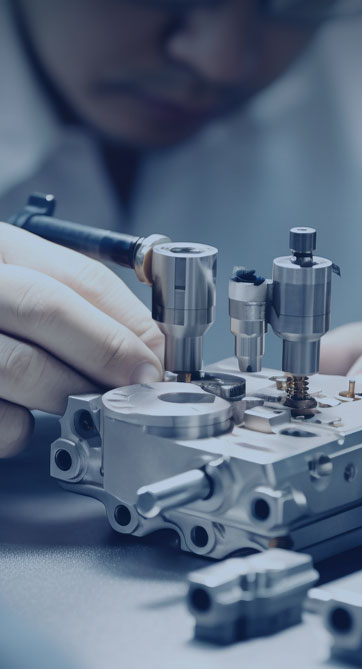

Quality Control

Production Line Control

• Fixed personnel, fixed positions + full production process traceability.

• Self-inspection on the production line + full-time inspection.

• Periodic inspection + outgoing inspection to ensure the reliable quality of materials

used inside the

devices.

Strict Inspection

Intermodulation test, microwave test, life test, stability test, coating inspection, high-temperature aging, thermal shock.

Product Service Center

Coaxial Switches

● Wide frequency range, up to 67GHz.

● Long service life and high transmission power.

● Low standing wave ratio, high isolation, low insertion loss, repeatability ≤ 0.05dB.

● Rich varieties, including SPDT, DPDT, SP4T, SP6T, SP10T, etc.