110G Precision and durable microwave test cable assembly

Application

Millimeter wave test platform

Lab/ R&D test

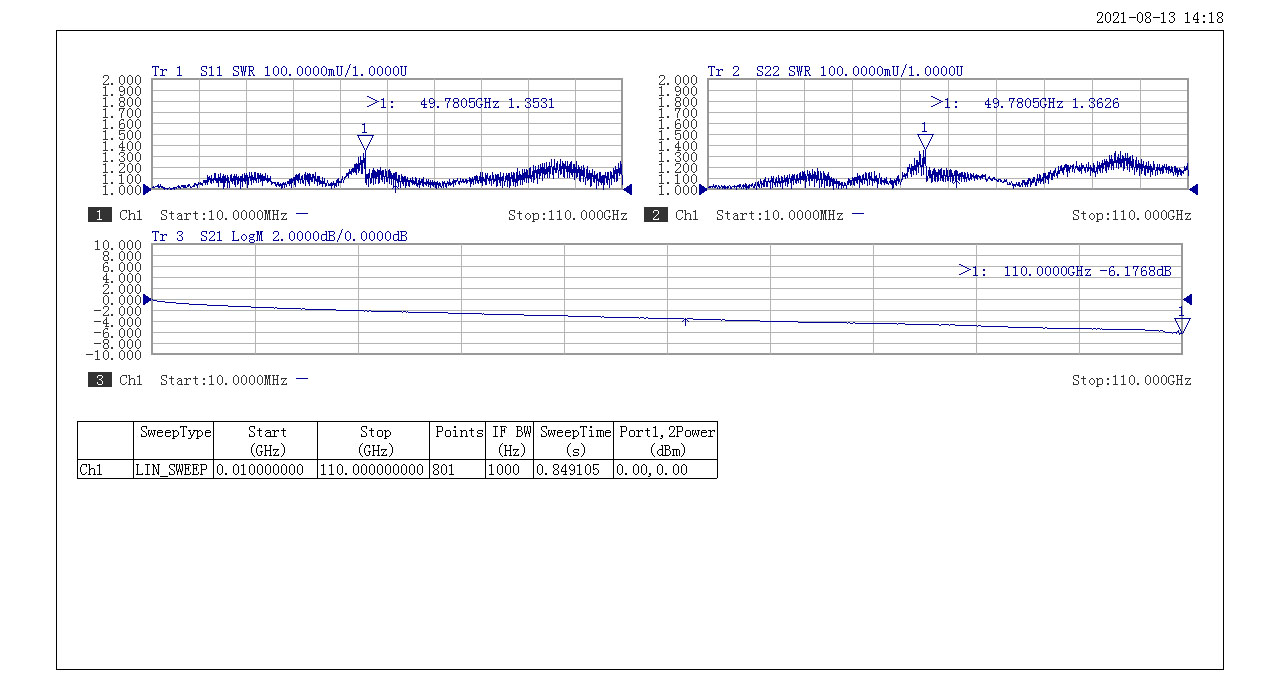

Test curve

How to use test cable assembly?

When using the test cable assembly, it must be tightened with a torque wrench, and the maximum torque specified by the connector must not be exceeded. The correct connector connection method is: after the male and female connectors of the same type are aligned, hold the female with one hand and rotate the male lock nut with the other hand, while ensuring that the inner and outer conductors do not rotate relative to each other. It is strictly prohibited to rotate the female connector for connection. If it is a nut with anti slip knurled structure, tighten it with fingers. When using the test cable, the bending times shall be minimized, otherwise the service life of the cable will be shortened. Due to the complex test environment, when bending is required, the bending radius cannot be less than the minimum bending radius of the cable itself. When using the test cable assembly, ensure that the test desk is clean, and any impact or extrusion may damage the electrical performance of the cable. It is strictly forbidden to install cable protective sleeves without permission to avoid damaging the mechanical structure of the cable and shortening its service life. After the test, the test cable shall be removed in time to check whether the connector interface is clean and damaged, and whether the interface depth is within the acceptable range. After confirmation, clean compressed air shall be used to blow off the debris attached to the surface of the medium, cover the protective cap, and store it in an appropriate environment. It is strictly prohibited to use defective test cables to avoid damaging the interface between the tested part and the test system and affecting the test accuracy of the tested part.